1. Product Overview

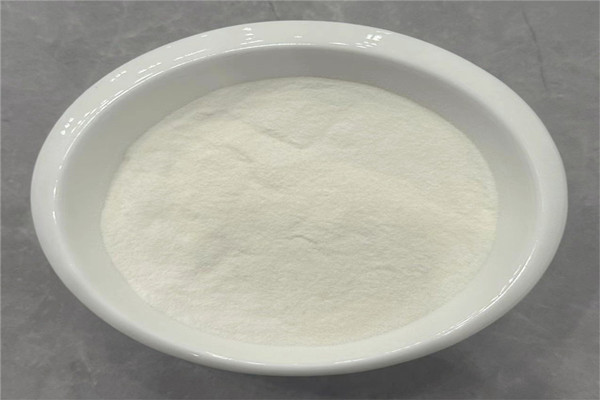

Sodium Lignosulfonate (SLS) is a natural anionic surfactant derived from sulfonated lignin, a byproduct of the paper industry. As a renewable, biodegradable polymer, it is widely used in concrete admixtures, dye dispersants, ceramic deflocculants, and oil drilling additives. In construction, it serves as a cost-effective water reducer and set retarder, offering both economic and environmental benefits.

2. Key Properties & Specifications

1. Physicochemical Characteristics

| Parameter | Specification |

|---|---|

| Appearance | Brown-yellow powder/liquid |

| pH (10% solution) | 8.0-10.0 |

| Water Solubility | Highly water-soluble |

| Molecular Weight | 2,000-50,000 Da |

| Sulfonation Degree | ≥1.8 mmol/g |

2. Functional Advantages

✅ Water Reduction – Lowers water-cement ratio by 10-15%, enhancing density

✅ Retardation – Extends initial setting by 1-3 hours (ideal for hot climates)

✅ Eco-Friendly – Biodegradable, sourced from recycled paper pulping waste

✅ Cost Efficiency – Priced 50-70% lower than synthetic alternatives

3. Primary Applications

1. Concrete Admixtures

Standard water reducer for ≤C40 concrete (dosage: 0.2-0.5%)

Retarding agent in blends with sodium gluconate for slump retention

Binder enhancer for bricks/gypsum boards

Case Study: A high-speed rail project achieved:

20kg cement savings per m³

12% higher 28-day compressive strength

15% lower construction costs

2. Dye & Pesticide Dispersant

Prevents agglomeration in dyes (0.5-1.5% dosage)

Key excipient for wettable powder (WP) pesticides

3. Oilfield Chemicals

Filtration control agent in drilling fluids (stable to 120°C)

Enhanced oil recovery (EOR) surfactant

4. Emerging Uses

Ceramic binder – Reduces cracking during drying

Lead-acid battery additive – Extends cycle life

4. Comparison with Synthetic Alternatives

| Criteria | Sodium Lignosulfonate | Naphthalene-Based | Polycarboxylate Ether |

|---|---|---|---|

| Source | Renewable (lignin) | Petroleum-based | Petrochemicals |

| Biodegradability | High | Low (contains formaldehyde) | Moderate |

| Cost (USD/ton) | 450-750 | 900-1,200 | 1,500-2,200 |

| Concrete Grade | C15-C40 | C50+ | SCC/UHPC |

Conclusion: SLS is the most sustainable and economical choice for rural infrastructure and mass construction projects.

5. Production & Quality Control

1. Manufacturing Process

Lignin extraction from paper pulping black liquor

Sulfonation with sulfites under high pressure

Neutralization & purification to remove impurities

Spray drying to powder or liquid concentrate

2. Critical Quality Metrics

Sulfonation degree (HPLC-tested) – Dictates solubility

Ash content ≤8% – Impacts water-reducing efficiency

Sugar content ≤5% – Excessive sugars delay setting

6. Market Trends & Innovations

High-Purity Modifications – Lower MW for better PCE compatibility

Hybrid Admixtures – Combined with silica fume for UHPC

Carbon Sequestration – Certifiable CO₂ fixation (2.5 tons/ton SLS)