For decades, byproducts have occupied the margins of industrial value chains — tolerated, managed, or discarded. But as the global push for low-carbon, circular production intensifies, materials once seen as industrial leftovers are being re-evaluated. One of the most compelling examples is lignosulfonates, a class of water-soluble polymers derived from the sulfite pulping process.

Once treated as nothing more than a disposal challenge for paper mills, lignosulfonates are now stepping into the spotlight as cost-effective, eco-compatible additives across multiple sectors — from construction and agriculture to mining, feed, and oilfield operations.

A Byproduct Rethought

Lignosulfonates are derived during the sulfite process of wood pulping. When lignin — the complex polymer that gives trees rigidity — is broken down, it can be sulfonated into a soluble form. The result: a multifunctional, anionic polymer with natural dispersing, chelating, and binding properties.

In the past, these substances were simply part of black liquor, burned for energy recovery. Today, they're being increasingly processed, standardized, and sold as industrial additives.

This shift isn’t just a matter of environmental responsibility — it’s about efficiency, utility, and market demand.

Why Industries Are Taking a Second Look

What makes lignosulfonates attractive isn’t just their origin — it’s their performance-to-cost ratio, coupled with their biodegradable, low-toxicity profile.

Key Advantages:

Natural dispersant for solids in suspension

Chelating agent for trace metals

Water retention improver in cementitious systems

Binder in pellets and granules

Anti-caking aid in fertilizers

Biodegradable and low environmental impact

While they may not always match the performance of high-end synthetic additives, lignosulfonates offer “good enough” solutions at a fraction of the price, particularly in volume-driven applications.

Global Applications Growing Quietly but Steadily

Lignosulfonates are now used in more than 20 industrial sectors. Here’s where they’re making a quiet but notable impact:

1. Construction and Cement Additives

Used as water reducers or plasticizers in ready-mix concrete, lignosulfonates help improve workability, reduce water content, and lower production costs — especially in low- to mid-grade concrete.

In cement grinding, they serve as grinding aids, improving mill efficiency and reducing energy use.

2. Agricultural Fertilizers

In NPK and trace element formulations, lignosulfonates act as binders and chelation agents, improving nutrient delivery while reducing dust and improving granule strength.

Their organic origin makes them more acceptable in eco-certified or sustainable fertilizer lines.

3. Animal Feed Industry

As pellet binders, lignosulfonates are widely used to improve mechanical stability of feed pellets — especially in poultry, swine, and aquatic feeds.

Compared to synthetic binders, they are safe, low-residue, and economical.

4. Oilfield Chemicals

In oil and gas drilling, lignosulfonates function as deflocculants and fluid loss control agents in water-based mud systems. They help maintain viscosity under high-temperature and high-pressure conditions.

Emerging Markets and Policy Push

The renewed interest in lignosulfonates is also being driven by international policies favoring biodegradable additives and phosphate-free formulations.

In the EU, regulatory pressure on synthetic dispersants is pushing formulators to explore natural alternatives.

In India and Southeast Asia, price-sensitive markets are prioritizing low-cost binders for fertilizers and feed.

In South America and Africa, construction growth and agricultural intensification are opening up demand for bulk-use additives.

With global supply increasingly supported by Chinese and European producers, lignosulfonates are positioned as one of the few byproduct-based chemicals with global market maturity.

Not Without Challenges

Despite the rising demand, lignosulfonates still face several hurdles:

Inconsistent quality due to variations in wood source and pulping methods

Lower performance in high-spec formulations compared to synthetic counterparts

Limited awareness among end-users and purchasing agents outside established sectors

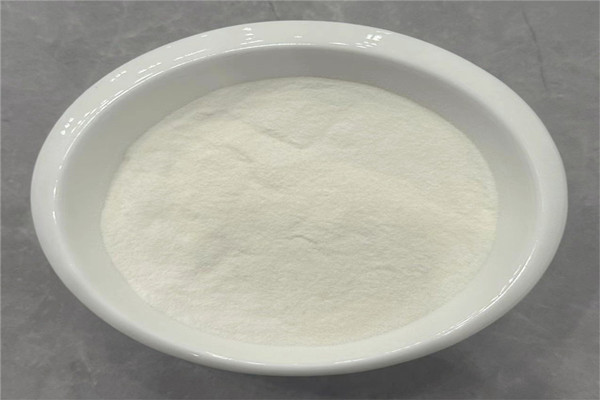

However, as standardization improves and technical grades diversify (sodium, calcium, ammonium, magnesium lignosulfonates in liquid and powder forms), these barriers are gradually diminishing.

The Road Ahead: Strategic Positioning Over Novelty

Lignosulfonates are not “new materials” — but they don’t need to be. Their value lies in pragmatism, scalability, and compatibility with sustainable practices.

In a world where supply chains are shifting and regulatory pressure on synthetic chemicals is increasing, industries are learning that “low-cost and low-impact” may sometimes be the best innovation.

And for lignosulfonates — long considered industrial leftovers — that realization is opening doors across continents and industries.